Cannons & Weapon Fittings

Metal Fittings on Carriage Preparing

Corel provides some brass fittings and most of them need to be blacken. So, I started this part by cutting the brass rod as axles, and blacken all the brass fittings together.

My mill vise can't grab the brass rods tight, so I used this method. Still slide a little bit, but didn't affect much. :)

The result...

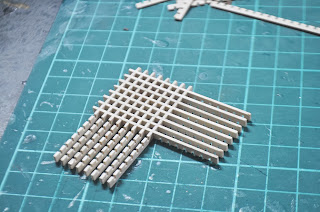

Total of 32 cannons, so.. 64 axles for the carriages.

Almost all brass fittings are in, besides the pump and bell. Yea.. Corel provides ready-made pump in brass. ;)

I added a brass wire in because the eyebolt provided by the kit seems oversize for me. I'll need to remake some eyebolts. For the cannons, they are in brown brass. I thought they can be still blacken, but they didn't work out.

After some minutes...

While waiting the blackening process, I continued on drilling holes for eyebolts. Here's the jig that I made to get equal position of the eye bolts. It took me almost whole night on this including adding the beds to the carriages (which I missed to take photos on the process).

The metals are left overnight in the solution , and the result looks satisfying. :)

I continued on the eyebolts making. To make them, I've made another jig. Just a hole beside a pin, pictures below show how I did them. :)

Plug the wire in the hole.

Coil it to the pin.

Cut at the end of the coil.

And then flatten it back. :)

Carriage Colouring

I am lucky to have a balsa board which is thick enough to hold the carriages, and it really eased my painting work. :D

A beautiful door frame? :P

Bottom and sides of the carriages after painting. :)

For the inner part, I painted them manually. Here you can see the bed that I previously added.

To colour the trucks, I used this method (I can sure this is a strange one :P ). I put as many trucks as possible into the 'pool' to make sure they are full and don't easily move, so that when I brush them they can stay in position.

The result is quite satisfying for me. Anyway, here's a problem that I didn't foresee. Since I didn't add a 'base' beneath it, I will need to turn them around almost one by one! If a base is added, I can just cover them with another piece of board, flip them over and start colouring the other side.

For the parameter painting, I used a brass wire to help on.

Now the eyebolts are good to put on. And of course, I added only on those which will be visible outboard. :)

Putting All Together

To put the axles on easier, I've made this.

The two slots will help the axles staying in position.

Then, I applied glue on the carriage, pushed it to the axles and let dry.

And then glued the trucks on. :)

Now, the major parts of cannons are basically done. I will add cap square to them when my copper sheet arrives, or perhaps some nails detail to them.

For the cannon rigging, Corel provides 3mm wooden blocks which are way oversize. Both blocks will be touching each other if they are made to tackle.

|

| Way Oversize Blocks |

So, I've now no idea what to do on the rigging. Either I'll skip the tackle and add only the rope securing the barrel button, or I'll buy or make smaller blocks like in 2mm length.

Hope I get a solution soon...

|

| Way Oversize Blocks |

Thanks for viewing. ^^