Day 5 to Day 11 - 20 Hours Work!!

With all the miniatures furnitures done, I've finally came to the planking part..

I've so much expectation on this because I didn't do the planking correctly on my Black Pearl.. So, I carried out this procedure very carefully. :)

Some say that the first planking should be done from the Garboard plank (lowest plank); while some say from the top.. Anyway, I started from the top as instructed in the manual (I regretted... :( )

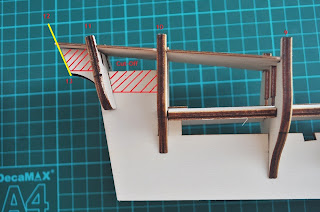

So, the first batten (temporary)!!

So, the first batten (temporary)!!

|

| The First Batten |

|

| Front View |

The first batten took me around an hour because I was so afraid of any mistake here will cause terrible result in the future.. And then, followed by the 2nd temporary batten which I put it 4 planks away from the first one (12mm), following a standard planking method as shown:

|

| How Temporary Battens Should Be Placed |

Anyway, I stopped using this method after the first 'slot'.. it is just too time consuming, and not so effective since the planks provided by the kit are not so equal in width..

|

| Tapering |

As you can see from the picture above, the 2nd and 3rd planks are tapered in the front end. It's done so because the planks on bow are 'curved' up, and hence making the planks 'over crowded' if they are not tapered.

|

| Over Tapered Aftermath |

Picture above shows the result of over-tapering, a flaw can be clearly seen. This is the reason I stopped using the method.. So, I continued on the garboard plank instead.

|

| Garboard Plank |

In a real ship, the garboard plank is usually wider; anyway, for a model ship it's ok to have the same width with other normal planks. I tested by using some waste wood strips before I use a new ones until it gave me the result like shown in picture above.

Same procedure is carried on until the plank touches each other at the bow side.

There is a Rule of Thumb of Planking says that plank tapering can never go exceed 1/2 of its own width.. For example, in my case my wood strips are 3mm in width, so I cannot taper it over 1.5mm.

Same procedure is carried on until the plank touches each other at the bow side.

|

| Check Symmetrical |

There is a Rule of Thumb of Planking says that plank tapering can never go exceed 1/2 of its own width.. For example, in my case my wood strips are 3mm in width, so I cannot taper it over 1.5mm.

Here's one good example of tapering I get from the net.. It's in Czech.

|

| Tapering Technique |

The sample above shows the correct way of planking, and the incorrect one below. Anyway, it's optional... it depends how much detail you want to make you model ship. :) Since I want to be ready for my 2nd layer planking, I used the 1st method! (MORE THAN 9 HOURS WORK!! :D)

|

| Body Planking Done |

|

| Tapering At Bow Side |

|

| Tapered Wood Strip |

The Bow and Body side are now done.. Let's see the stern part..

So, this is the result at the stern side.. and it's time for the Stealers!!

|

| Stealer Needed To Fill Up Gaps |

This picture basically explain what a stealer is. Since the wood strips are curving and twisting too much, they will cause gaps at one end. To fill up those spaces, we need stealer planks.

|

| How Stealer Planks Help Filling Up Gaps |

Here's how I do it!! One full stealer and one half stealer

|

| Full and Half Stealers Added |

Full View with poop & front deck planking completed!

|

| 1st Planking Done Starboard Side |

You can actually see a 'hole' there at the stern side as I trimmed the woods too early before I know they will need to cover that part.. :( Anyway, it can be easily filled up by filler! :D

|

| 1st Planking Done Bow Side |

|

| 1st Planking Done Stern Side |

Since the first plank was positioned, it's around 20 hours of working!! Maybe I'm still new in planking, that's why it took me so much time.. Anyway, the whole process was just so enjoying and the result is kinda satisfying! (for me :D)

- End of Day 11-